Biodegradable Polyesters

(Biobased) Aliphatic Polyesters

Properties

In the

last two decades, much attention has been given to the development

and application of biodegradable polymers. They can be classified

into two types according to the preparation method; the first class are polymers

synthesized from renewable sources, and the other class are

synthetic, mostly from mineral

oil derived polymers that are

biodegradable.

One of the most important biodegradable polymers are (biobased) aliphatic polyesters. Many of them have excellent biodegradability and biocompatibility and are, therefore, a very important class of biodegradable polymers. There are numerous aliphatic biodegradable polyesters. However, only a small number of them are commercially availabe. Some biobased polyesters that have gained commercial use or that are currently investigated for commercial use are polylactic acid (PLA), polyglycolic acid (PGA), poly-ε-caprolactone (PCL), polyhydroxybutyrate (PHB), and poly(3-hydroxy valerate). Among these, PHB and PLA are probably the most extensively studied biodegradable thermoplastic polyesters. Both are a truly biodegradable and biocompatible and both have a relatively high melting point (160 to 180 °C). However, practical applications have often been limited by their brittleness and narrow processing window. Therefore, blending with other polymers has been often reported in the literature.

Important synthetic biodegradable polyesters are poly(ethylene succinate) (PESu), poly(propylene succinate) (PPSu) and poly(butylene succinate) (PBSu) among several others. They are typically produced from the reaction of a diacid or acid anhydride with a diol with the elimination of water. Most aliphatic polyesters are currently produced from fossil fuels. However, some of these polyesters can also be produced using monomers from renewable resources. Many succinates have been intensively studied due to their inherent biodegradability and commercial availability. PPSu has gained an increasing interest because its biodegradation rate is higher than those of most other succinates like poly(ethylene succinate) (PESu) and poly(butylene succinate) (PBSu). Due to its low crystallinity, it also degrades faster than most other polyesters used as pharmaceutical excipients including polycaprolactone (PCL).

The majority of biobased or biodegradable polyesters are completely aliphatic. They usually have a low melting point and glass transition temperature and poor hydrolytic stability, that is, they are rather hydrophilic and, therefore, will have a moderate to high water uptake when exposed to moisture. This will effect the mechanical properties and stability. For this reason, some biodegradable polymers have been blended with more stable polymers or have been copolymerized with aromatic building blocks (aromatic acids or anhydrides). For example, poly(butylene adipate-co-terephthalate) (PBAT) is commercially synthesized from adipic acid, terephthalic acid, and 1,4-butane diol.

An important property of biodegradable polyesters is the degradation time, which should be as short as possible in regard to disposal. However, corrosion resistance might decrease too strongly when the polymer has a very short degradation time. Depending upon the polymer and the conditions, degradation times will range from several months to several years.

Tensile properties are usually best for those with the smallest molar volume (highest packing density). Especially strong are PGA and PLA, whereas PCL, on the other hand, is the softest polymer with an extraordinary high strain at failure. A very important factor is the molecular weight (MW). Varying the MW will yield polyesters with very different mechanical properties. For example, the tensile strength of PLA can vary between 1 and 150 MPa. Another important factor is tacticity. Many aliphatic polyesters have an asymmetrical carbon atom in the repeat unit which enables it to become optically active. For example, it is possible to obtain isotactic L-PLA or D-PLA and syndiotactic DL-PLA consisting of alternating L- and D-units. These polymers have very different mechanical properties. For example, L-PLA has two to three times higher tensile strength and Young’s modulus than DL-PLA.

Aliphatic polyesters are often blended with other resins to improve their processing and end use properties. For example, they can be blended with starch to lower cost and to increase the biodegradability. Biodegradable polyesters are also used as the matrix resin for mostly unidirectional bio-composite materials. Often natural fibers like flax, hemp, jute, bamboo, elephant grass, and kenaf are used as reinforcing fibers. For composites, the mechanical properties of the polyesters are not very important since the reinforcing fibers provide most of the composite strength. PLA and PCL seem to lead to the lightest composites with a relatively high fiber content, which is often desirable since this results in less use of expensive resin. It seems the softer the matrix polymer is, the lighter the resulting composite will be, while the mechanical properties of the composite seem hardly affected at all.

The development of bioplastics has gained a lot attention in recent years. Only time will tell whether these new plastics will gain a significant marketshare. This will partly depend on how strongly society is commited to protect the environment, i.e. to reduce waste, and to conserve irreplaceable fossil fuels.

Many obstacles such as high price, limited production, and inferior (mechanical) performance have to be overcome before these novel biodegradable and/or biobased polymers will gain a significant market share.

| Polyester | Structure of Repeat Unit | Properties |

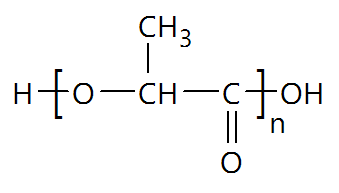

| Poly(lactic acid) or Polylactide (PLA) |

| Tg ≈ 45 - 60 °C Tm ≈ 150 - 160 °C |

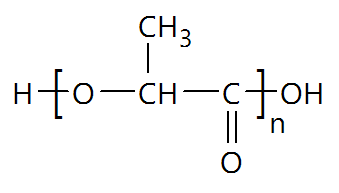

| Poly(L-lactic acid) or Poly(L-lactide) (L-PLA) |

| Tg ≈ 55 - 65 °C Tm ≈ 170 - 200 °C |

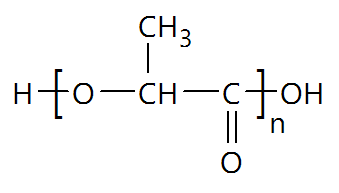

| Poly(DL-lactic acid) or Poly(DL-lactide) (DL-PLA) |

| Tg ≈ 50 - 60 °C Tm ≈ N/A (am.) |

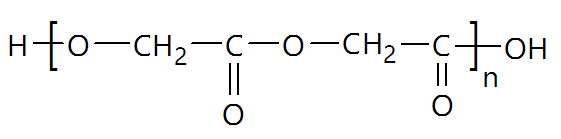

| Poly(glycolic acid) or Polyglycolide (PGA) |

| Tg ≈ 35 - 45 °C Tm ≈ 220 - 235 °C |

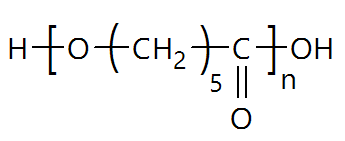

| Poly(ε-caprolactone) (PCL) |

| Tg ≈ -60 - (-65) °C Tm ≈ 58 - 65 °C |

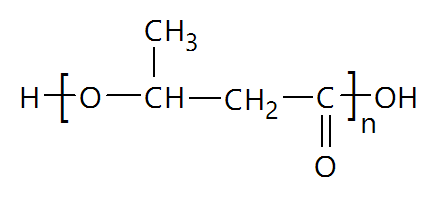

| Poly(hydroxybutyrate) (PHB) |

| Tg ≈ 5 - 15 °C Tm ≈ 165 - 180 °C |

COMMERCIAL Biobased or Biodegradable POLYESTERS

Major manufacturers of unfilled and filled bioplastics include NatureWorks, BioMatera, Perstop, Solvay, Novamont, Mitsui, Corbion and Dow.

The most common and most promising bioplastic is polylactic acid. First, corn or other biomaterial is fermented to produce lactic acid, which is then polymerized to polylactic acid (PLA). The demand for PLA is expected to grow from 0.1 Mta today to 2Mta over the next few years.3

APPLICATIONS

Aliphatic polyesters

and other biopolymers have found many applications in medicine

and pharmaceutical technology, for example, in drug delivery

systems, wound

closure, surgical sutures, implants, and tissue

engineering.

Drug delivery inside the human body can be relatively easily

controlled with biodegradable capsules. In wound healing,

resorbable nonwovens are used as replacement of human tissue.

Most biodegradable polymers are currently not widely used in other applications due to some limitations such as higher cost, inferior mechanical properties, and lower environmental and chemical resistance, or in other words, only a small number of biodegradable polyesters have found limited use outside the medical and pharmaceutical industry. One is PLA and blends of it that are currently used as a feedstock for injection-molding of disposable articles like drinking cups and food containers. Some other (potential) applications include soil retention sheething and other agriculture films, waste bags, and the use as packaging material in general.

The market share of biodegradable polymers is currently (2016) rather small but is expected to grow.4

References and Notes